Key Characteristics of Cement Clinker

- Composition

- Mainly consists of calcium silicates, such as alite (C₃S) and belite (C₂S), along with smaller amounts of aluminates and ferrites.

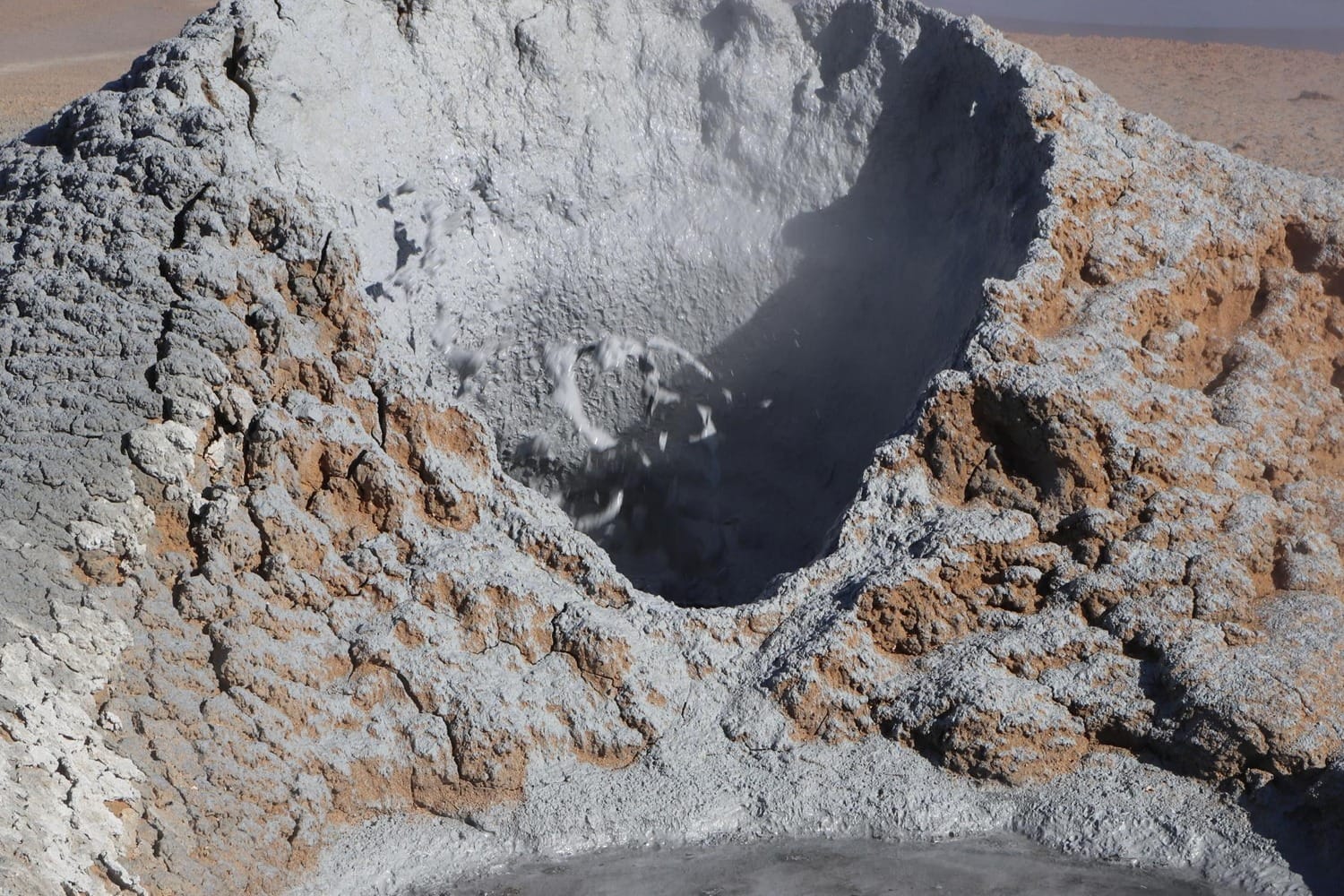

- Appearance

- Appears as small, dark gray to black, pebble-like nodules.

- Formation Process

- Raw materials are heated in a kiln at temperatures of about 1400–1500°C.

- This high heat causes a chemical reaction (clinkering) where the raw materials fuse together.

Applications

- Cement Production

- Ground clinker mixed with gypsum and sometimes other additives is milled to produce different types of cement, such as Portland cement.

- Export

- Often exported to regions lacking cement production facilities.

Importance

- Clinker is the backbone of the cement industry, serving as the essential material for making durable construction materials like concrete and mortar.